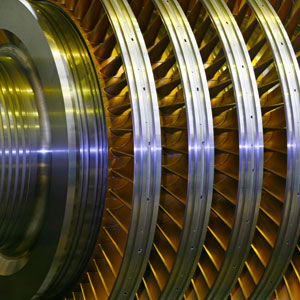

Power Generation Castings Densification

- Gas Turbine Blades

- Shafts, Discs & Blisks

- Structural Components

In the power generation industry, hot isostatic pressing (HIP) is used to densify components to remove porosity and enhance performance. For example, high temperature airfoils in power-generation gas turbines are HIPped to extend their life and avoid premature failure. HIPping is also used to produce structural parts for the nuclear industry.

Advantages:

- HIP densified castings show improved strength, ductility and fatigue life with significantly less variation from casting to casting. The improved and more consistent material properties reduces part over design. This also decreases quality assurance costs and opens new applications.

- By removing service-induced porosity, HIP rejuvenates castings, extending their service life for improved economy.

- Hot isostatic pressing salvages castings scrapped for internal porosity - in fact, it is the only effective way to repair porous castings. Casting yield is significantly improved, resulting in lower costs and more effective utilization of raw materials.

- Significant cost savings may be realized by starting with a cast part and then HIPping to improve its properties as compared to machining the part from a solid.

Materials that typically can be densified using HIP:

- Aluminum alloy castings

- Composites

- Cobalt chromium alloy castings

- Stainless steel castings

- Alloy steel castings

- Superalloy castings

- Titanium castings